When it comes to grinding...

You should be talking to Us

Profimach CNC Grinders

Full line of grinding Solutions

Carbide Blanks grinding production redefined!

Carbide blanks pre-grinding: saving money and time and boost your other grinding production.

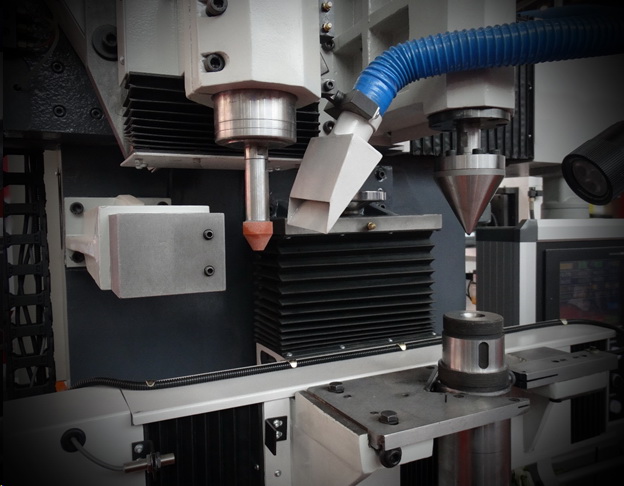

Profimach® PG-CBPG-175. This new range of premium Carbide Blank Profile Grinder sets standards in his category. Its values are simplicity, modernity, innovation and robustness allied with a never seen price/performance ratio.

The perfect harmonization of both machining performances and stability is the fruit of innovation efforts based on the long experience of our engineers. The result is reliable high precision production equipment with an irreproachable operation in any situation.

The generous standard equipment underlines the versatility of this concept of the latest generation.

Today this new machine opens the horizon to new performances and quality levels within your daily production of Carbide Blanks at an affordable price.

PROFIMACH PG-CBC-40-Series

Automatic Carbide Blanks cutting production redefined!

Profimach® PG-CBC-40-series. This new range of premium Carbide Blank Cutter sets standards in his category. Its values are simplicity, modernity, innovation and robustness allied with a never seen price/performance ratio.

The machine design, optimized by means of state of the art simulation and analysis tools provide solidity throughout the machine. The result is a stable grinding behavior which ensures a lasting quality of a high accuracy production process.

The perfect harmonization of both machining performances and stability is the fruit of innovation efforts based on the long experience of our engineers. The result is reliable high precision production equipment with an irreproachable operation in any situation.

The generous standard equipment underlines the versatility of this concept of the latest generation.

Profimach CNC Centre Hole Grinding Machine

In pursuit of Higher Center Accuracy

There is much scope for error in drilled center holes; misalignment, out-of-round, 60-degree angle too large or too small, lobed and certainly with a poor surface finish.

If the center-drilled hole has the wrong angle, is too small or too shallow, or is damaged, the live center does not have enough contact with the workpiece to properly stabilize the cut. This causes chatter, accuracy, and tool life issues.

Wouldn’t it be wonderful if super precise grinding can be actualized with your currently available cylindrical grinding machines?

Your products may not be competitive enough if their circularity is not quite satisfied or cylindricity varies. Are such issues only because of your cylindrical grinding machine?

Causes of geometry faults such as improper circularity and cylindricity as well as surface roughness could be the insufficient machine precision or the un-balance of grinding stones. However, in many cases, all those issues may be caused by the accuracy of the “Center hole”.

More info on our CNC center hole grinder

More info on this product?

West Europe :

Call +32 475.736.351 - Patrick (Nederlands, Français, English, Deutsch )

East Europe :

Call +40 722.346.170 - Cézar (English, Français, Română)

or call +40 755.088.805 - Catalin (English, Română)