Permanent electro magnetic chucks for milling, turning, grinding, edm.

How does an electro magnetic permanent chuck works?

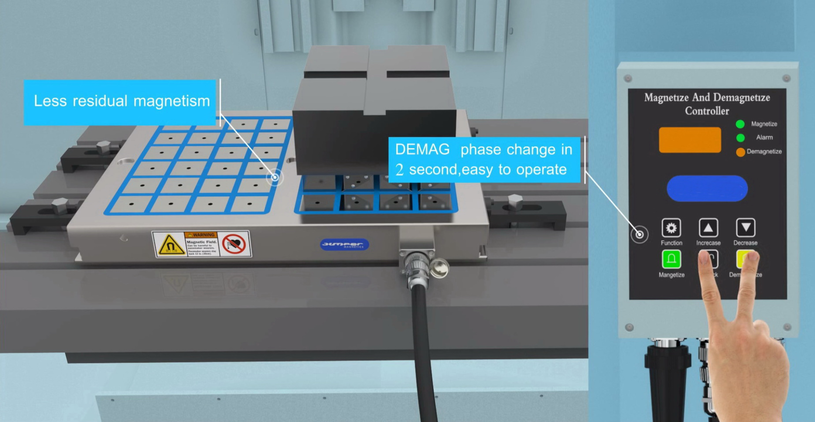

The electric magnetic permanent chuck (electromagnetic permanent chuck) is a new type magnetic chuck using electric pulse for "switch On and switch Off" holding force.

It results in an endless permanent magnetic force, so it’s safe and reliable for the magnetic chuck to hold work pieces.

The "On/Off" switching can be done within one second, which will ensure little electric pules power consumption and non-heat-deformation of the chuck.

These magnetic chucks have no sliding parts as ordinary permanent chuck, which results in a stable, firm and high-precision structure.

SAVING ENERGY!

High quality construction

High energy savings: only 2 sec activation for days of clamping.

Rigid Single piece steel body frame

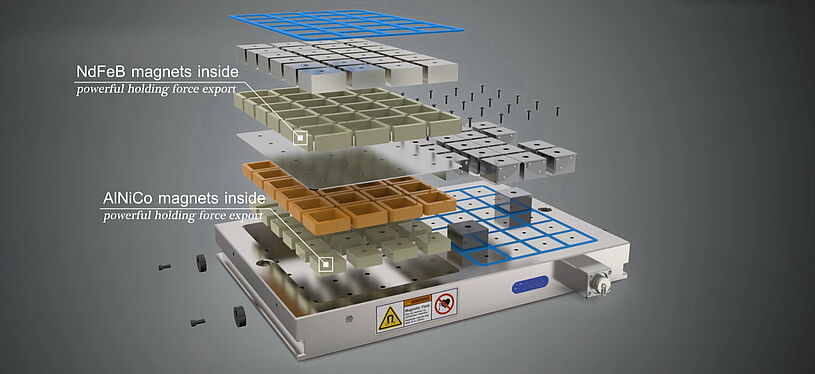

Dual layer high performance Magnets

Each magnetic pole is surrounded by permanent magnets. Magnets wound with a coil of wire that carries an electric current are embedded in the lower parts of each magnetic pole. These coiled magnets can reverse the magnetization directions of the magnetic poles. The magnetization directions can be changed within seconds using the current directions of the wire coil. Consequently, magnetic fields are formed around the magnets, which enable the chuck to clamp workpieces. Conversely, the magnetization directions of the magnetic poles can be internally offset by those of the permanent magnets. This consequently eliminates the magnetic fields around the magnets, thereby demagnetizing the machine tool.

Simple control system

2 seconds to activate or deactivate magnetism

Magnetic workholding modules for milling

MANUFACTURING

As the main featured products of CNC Europe Magnetic chucks division, our affordable electro permanent magnetic chucks could be widely used for milling, grinding, turning, EDM and other applications, with the help of various kind of pole extensions. The performance features of your machine tools and machining centres will unfold their full potential because you’ll be able to machine all five sides of your workpiece during a single setup.

With our 10 years experience in magnetic workholding & lifting industries, CNC europe Magnetics keep on optimizing our design of products.

Frame:Considering to traditional welded steel frame, Jumper magnetics use monoblock steel frame which machining from one iron block. This could improve the strength and flatness of EPM chucks. And on the other side, monoblock structure could also avoid short circuit because of coolant water/oil.

Copper coil circuit: The copper coil circuit inside(EPM chucks) have better electrical conductivity than aluminum coil of Electromagnetic chucks. Copper have betters conductivity properties than Al, and the service life is much longer. Each coil contact with tin soldering, makes the connection more stable.

Epoxy resin: The gap of the surface are fulfiled with two-layer high performance epoxy resin. One layer to fill in the gaps of the inside coils and magnets. After at least 36h drying, another layer of epoxy resin will fill on the surface. Drying time play an important role in the waterproof properties of chuck.

NdFeB/AlNiCo Magnets: We choose the high performance N45 magnet as raw material. All the magnets are electroplated with Ni/Zn/Cr, so that they could keep good magnetism properties even at acid/soda/salt environment.

IP 67 waterproof connector: The connector are imported from Korea with IP 67 waterproof design. All the connect part are flexible connection with grease proofing elasticity material.

Pole extensions: The pole extensions could help to prevent the surface from wearing of workpiece. Besides, Flexible pole extensions and speacial poles could design according to customers request.

Control systems: The fifth generation of control system for EPM chucks have 8 level holding force adjustment control. With extra inspection buttons, our customers could find the breakdown reason due to coresponding code number.